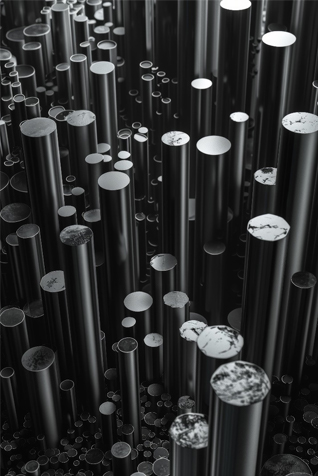

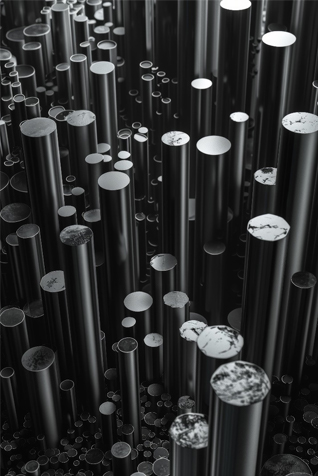

Properties of Stainless-Steel Black Bars

Date : Feb 12, 2025

Black bars Stainless Steel are semi-finished steel production widely used for their strength, durability and resistance to corrosion. The bars of these types of nuts have dark, oxidized surface and due to the process of manufacturing, these bars offer better wear resistance.

Key properties include:

- Corrosion Resistance: Perfect for usage in areas that have many changes in humidity, usage of chemicals and fluctuating temperatures.

- High Strength: Well suited for demanding applications due to the outstanding mechanical characteristics possessed by these materials.

- Versatility: It is found in different grades namely: 410, 416 and standard 420 with variation depending on the industrial usage.

- Aesthetic Appeal: The oxide coating affords a rough surface that may be sanded smooth to give an art like appearance.

- Raw Material Selection: Quality stainless steel billets or ingots are selected according to grade and application required.

- Heating: The billets are heated in a furnace to make it plastic.

- Hot Rolling: The hot billets are passed through rollers to get the desired shape and size.

- Cooling: Rolled bars are cooled at room temperature, allowing oxidation of the surface naturally, thereby giving the black finish.

- Cutting and Shaping: The bars are cut into standard or custom lengths and shaped according to requirement.

- Quality Testing: Final products pass strict quality checks before leaving the unit to meet all industry standards.

Common Applications of Stainless-Steel Black Bars

Stainless steel black bars are found to be utilized widely in many different sectors because of its strength properties. Major application fields include the following:

Construction and Infrastructure

Concrete reinforcement.

Framing, railings, and other structural elements.

- Automotive: Shafts, axles, fasteners, parts needing high tensile strength along with resistance against corrosion

- Manufacturing and Engineering: Machine parts, tools, equipment, heavy machinery, and industrial facilities

- Oil and Gas: Equipments used in corrosion environments such as pipelines, rigs, etc.

- Aerospace and Defense: High performance parts used for extreme applications

- Ornamental and Artistic Applications: For architectural designs, sculptures due to the special appearance.