Benefits and Types of Stainless Steel 400 Series

Date : Jan 29, 2024

Stainless steel is a robust and commonly used material, it is recognized for its durability and durability against corrosion, and appeal. It’s consisted 10.5% chromium, which preventive oxide layer that can safe an alloy of steel from rust and staining. This will make it isan important material for a variety of applications, from basic kitchenware to construction projects.

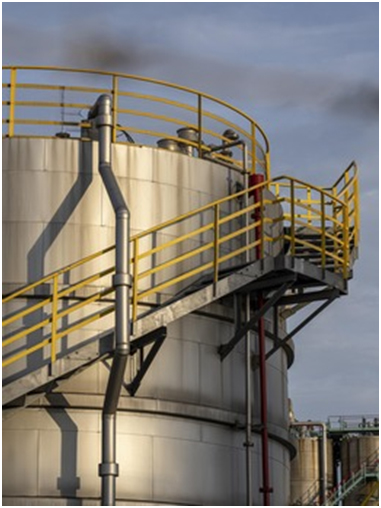

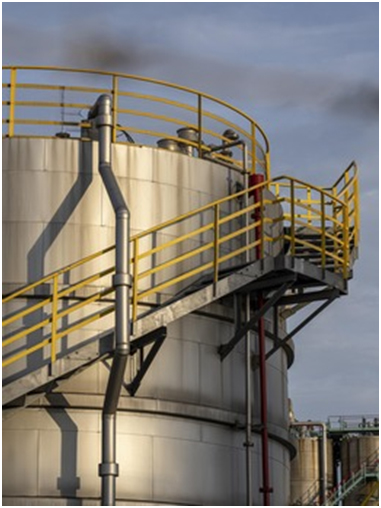

Our stainless steel is corrosion resistance it commonly used for kitchen & cutlery, and medical and surgical application, while its strength finds it in architecture and construction and even automotive parts. Its hygienic surface keeps things clean in food processing and chemical and petroleum industry.

What Material is Used to Make Stainless Steel?

Stainless steel consists of a low carbon steel alloys along with an average of 18% of chromium and consist of silicon and manganese. Nickel and molybdenum also appear to improve it corrosion resistance in some grades. Chromium provides durability by hardening and increasing its corrosion resistance in heat.

What are the Types of Stainless Steel?

- Ferritic: Ferritic steel packs a punch with over 12% chromium, making it rust-resistant and tough. Plus, it's easier on your wallet compared to other types.

- Magnetic and a bit less flashy: Ferritic is attracted to magnets and has a slightly matte finish. Think car exhaust systems and building materials where looks aren't the main focus.

- Austenitic: The bendy, weldable charmer, like your trusty kitchen sink. Think 304 and 316 grades, gleaming and non-magnetic.

- Duplex: It is a combining austenitic and ferritic power for oil rigs and ocean adventures. Super strong and corrosion-resistant.

- Precipitation-hardening: The high-flying ace, soaring through the skies in aircraft parts. Its special heat treatment gives it top strength and corrosion resistance.

Focusing on 400 Grade Series of Stainless Steel

- Stainless Steel 409: For high-temperature applications like car exhausts.

- Stainless Steel 410: Making valves, pumps, pipe fittings, and parts for petroleum refining and chemical processing equipment, producing firearm barrels and Developing steam turbine blades and other power generation partsand other components.

- Stainless Steel 416: Making automatic screw machine parts, Manufacturing washing machine components, firearm barrels, and marine hardware13,Developing springs, washers, and other elastic components.

- Stainless Steel 420: Making knife blades, scissors, surgical instruments, and other cutting tools. It can also be used for making valves, pumps, bearings, and other components that require wear resistance and durability.

- Stainless Steel 430: The go-to for appliances and building trim.

- Stainless Steel 430 F: Producing fasteners, screws, bolts, nuts, solenoids, Gears, Shafts,Pinionsand other hardware items, Developing springs, washers, and other elastic components.

- Stainless Steel 431: Producing firearm barrels and other parts that need both strength and corrosion resistance, developing aircraft parts, marine components, pump and propeller shafts, and other applications that require high tensile strength and toughness etc.

- Stainless Steel 440 A/B/C: It is often used for making knife blades, scissors, surgical instruments, and other cutting tools. It can also be used for making valves, pumps, bearings, and other components that require durability and toughness.

- Stainless Steel 446: Extra corrosion-resistant for things like hot water tanks.

The 400 Series And Its Benefits

The 400 stainless steel grade is tough and affordable with lower chromium but higher carbon content. They're not as corrosion-resistant as 300 series, but they're stronger and more weldable, making them ideal for cutlery, car parts, and decorative applications and manymore.

- Super Strong: Handles wear and tear with ease, making it ideal for things like cutlery, tools, and machinery.

- Holds its shape: Doesn't bend or warp under pressure, perfect for construction and automotive applications.

- Weldable and machinable: Easy to work with, making it a versatile choice for manufacturers.

- Affordable: More budget-friendly than some other stainless steels.